DOE: Variability First, Mean Second

Design of Experiments (DOE) is a fundamental approach in engineering and scientific research that enables systematic study of the relationships between multiple input variables (factors) and one or more output responses (signals). For mechanical engineers and those working on product validation, reliability, and performance optimization, DOE offers a structured method for identifying, quantifying, and controlling the influential factors. A successful DOE not only reveals the contributors to the average performance (mean) but also highlights what factors, or their combinations, influence the variability (noise) in a process or measurement.

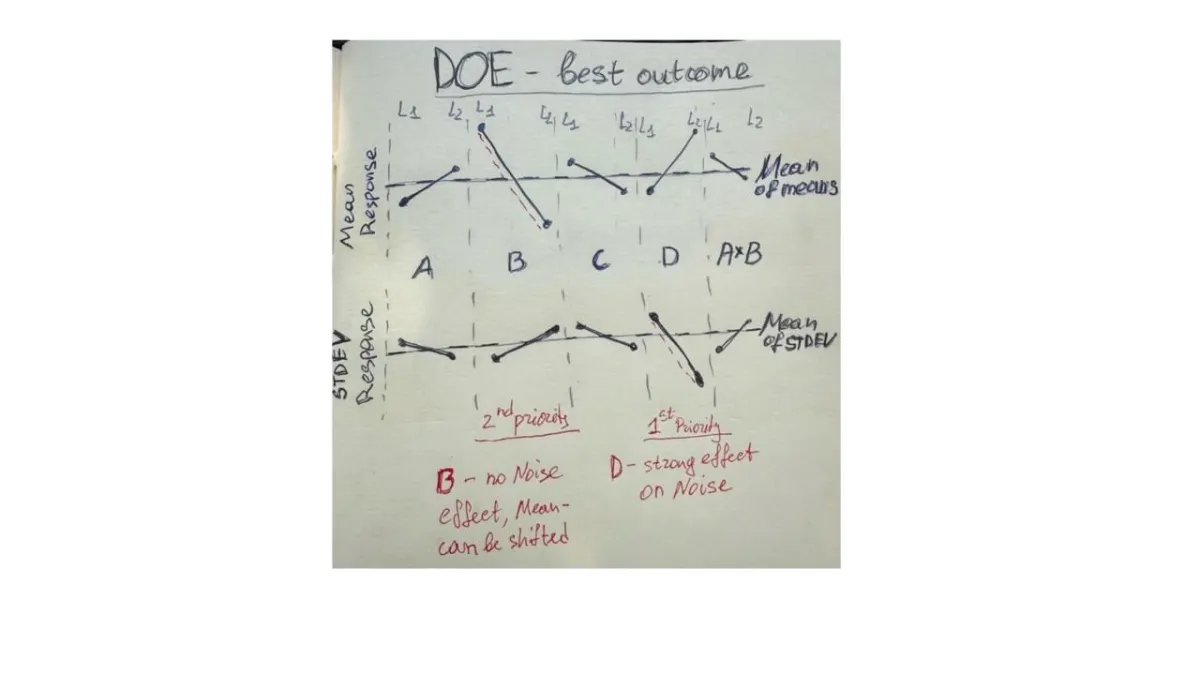

A vital—yet sometimes underemphasized—aspect of DOE analysis is understanding how different factors impact the variability of the output. Variability is frequently expressed as the standard deviation (STDE) under the assumption of normal data distributions. High variability (noise) in a signal can mask trends, complicate predictions, and undermine reliability, especially in validation and long-term fatigue or run-to-failure testing. Therefore, during factor analysis, priority should be given to identifying which variables, or interactions between them, most significantly affect signal variability.

After addressing which factors drive variability, attention should shift to identifying the main contributors to the mean output signal. The mean represents the average response under various configurations, and knowing which factors predominantly affect it helps engineers fine-tune performance to meet product requirements or regulatory limits. Ignoring variability and focusing solely on the mean can result in designs that, although optimal on average, are vulnerable to real-world fluctuations and less robust overall.

Imagine a mechanical subsystem where several factors—load, temperature, lubricant type, and speed—are varied systematically using a factorial DOE. Suppose the primary output signals measured are the time to failure (reliability) and the vibration amplitude (a marker for performance and structural health). Analyzing this system using the DOE approach, the first step is to identify which factors or their interactions cause the vibration amplitude’s variability to spike. For example, it may be found that lubricant type and temperature together significantly increase standard deviation, indicating a need to address this combination in future product optimizations or reliability specs.

DOE provides statistical tools—such as analysis of variance (ANOVA), interaction plots, and regression modeling—that help dissect the contribution of each factor both to variability and to mean performance. Interactions between factors, such as how speed at different temperatures affects reliability noise, can be just as critical as main effects. Sometimes, a factor may have a negligible effect on the mean but a substantial influence on the standard deviation, which is essential for noise reduction and making robust design choices.

The insights from factor analysis drive practical decisions in product and process development. By identifying and controlling those factors that most strongly affect variability (noise), engineers can create processes or designs that are more robust against external disturbances and manufacturing tolerances. Once noise contributors are minimized, tuning the mean becomes more effective and repeatable, as the process is no longer as susceptible to hidden or interacting sources of fluctuation.

Key best practices in DOE data analysis include visualizing data through main effects and interaction plots, quantifying factor significance (often via p-values and confidence intervals), and always considering both main effects and interactions in the context of variability first, followed by mean shift. Running confirmation experiments or validation studies further strengthens confidence in findings and ensures real-world repeatability.

A comprehensive DOE process is not just about finding which factors push the mean to a desired value but critically about managing and minimizing noise. By first understanding and controlling those factors that drive variability, you lay the groundwork for more predictable, reliable, and robust engineering solutions. Only after stabilizing variability should the focus shift to optimizing the mean, ensuring that product performance is both consistently high and reproducible in real operating conditions. This dual focus on noise and mean effect is the hallmark of a professionally executed DOE and robust engineering practice.