The Blog

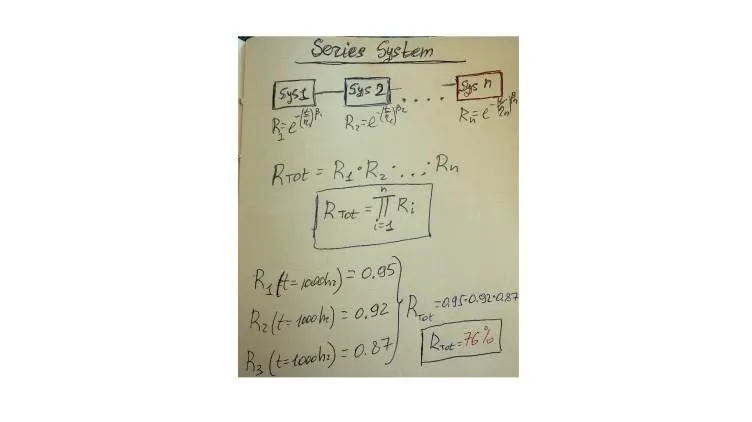

Series-Connected Subsystems

Complex electromechanical products rarely rely on a single mechanism; they knit together motors, sensors, power electronics, and software into an interdependent whole. When these blocks are wired in series, the entire device goes down the instant any subsystem fails. That architecture pushes reliability engineering beyond component datasheets and into system-level control strategy: monitoring health, throttling loads, and reconfiguring operation can prevent a looming fault in one block from propagating into a full-product shutdown. Rigorous validation is the other half of the defense. Conventional qualification verifies each part in isolation, but series connection demands excessive (high-margin) tests—accelerated life cycling where temperature, vibration, duty factor, or electrical stress are elevated well beyond specification. By forcing early failures and identifying the true weakest link, engineers gain the data they need to fine-tune control algorithms, upgrade materials, or add redundancy before devices reach the field and customers feel the pain.

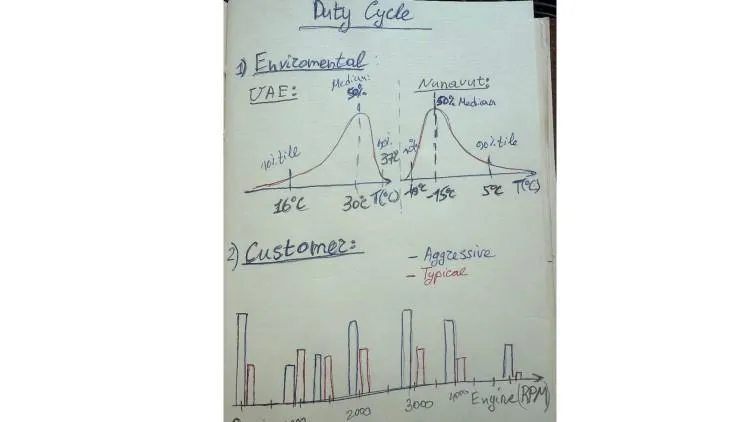

Duty Cycle Engineering

A clearly defined duty cycle—the time-weighted map of every load, rest period and environmental exposure a product sees—anchors both design and testing. When engineers know how long a motor will dwell near its thermal limit or how often a valve will switch, they can right-size components, predict bearing life, and prevent heat-driven failures instead of over-building for worst-case guesses. This stress “budget” also exposes interactions a single load can’t reveal, such as high current plus elevated temperature that doubles copper losses in a drive circuit. That same map becomes the blueprint for reliability work. Automated duty-cycle tests replicate months of field use in days, uncovering latent fatigue cracks, seal leaks or electronic drift long before launch. It lets teams pick actuators with the correct duty-cycle rating so coils stay below safe temperatures, and choose motor-control strategies that match the intended start-stop cadence. In short, defining the duty cycle early converts vague “real-world conditions” into objective, testable limits—cutting warranty cost, shortening validation loops and delivering products that survive both gentle daily use and the occasional hard-charging outlier.

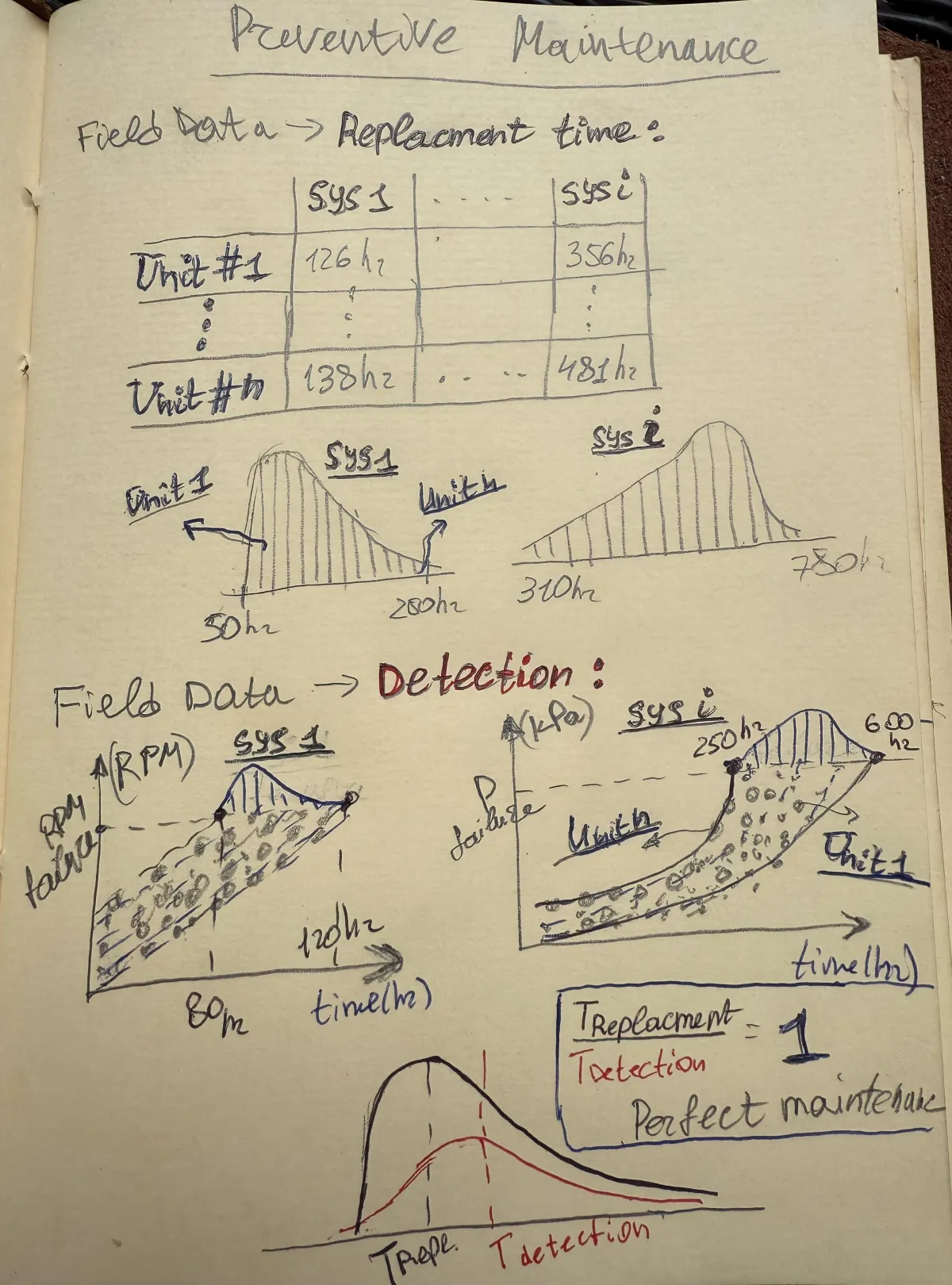

Preventive maintenance: Replacement vs. Detection

Two mindsets dominate preventive maintenance. Time-based replacement swaps parts after a fixed number of hours, cycles, or calendar days; its simplicity and regulatory compliance keep it the workhorse for many plants.

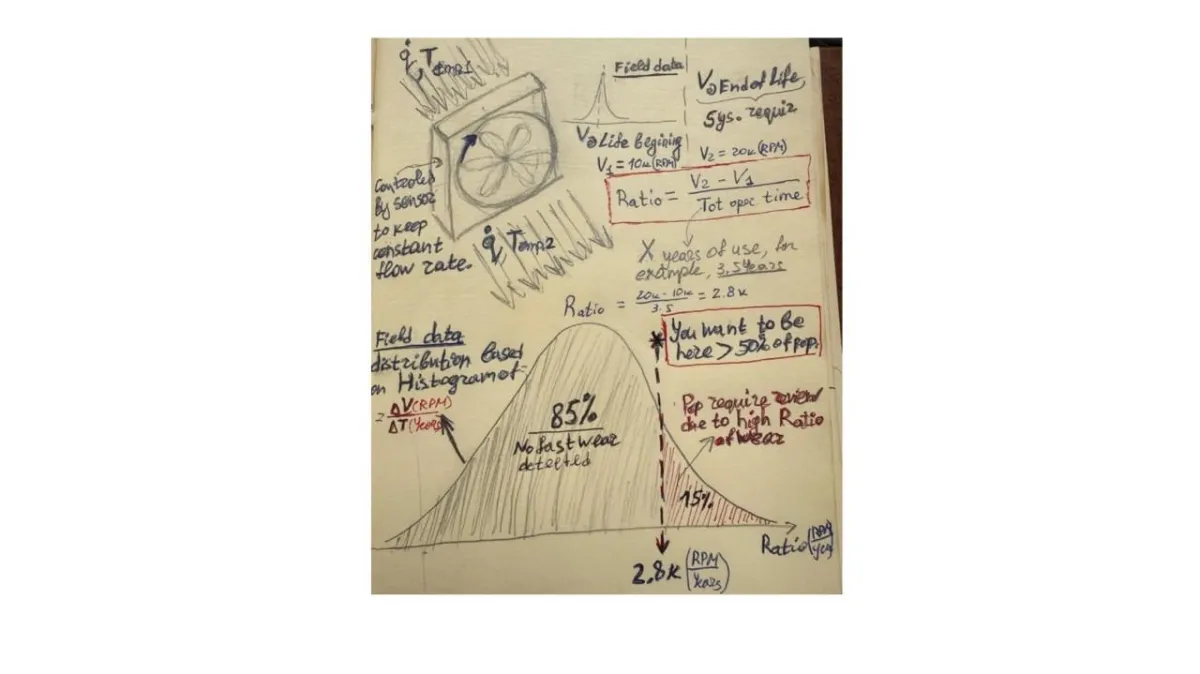

Data-Driven Detection of Accelerated Wear in Critical System Components.

Data-Driven Detection of Accelerated Wear in Critical System Components.