About Me

From product vision to measurable results

• 15 years of experience in a R&D, manufacturing environment, experience with multidisciplinary team in the Large Format Printing, Automotive, Hydrogen Fuel Cell and Medical industries.

• RTF (run to failure approach), Weibull++ analysis of data, test definition

• Experienced in test definition through tools such as Design Of Experiment (DOE) and Root Cause Diagram (RCD)

• Experience in product validation, product development processes

• Experienced in CFD (ANSYS CFX) and thermal mockups to validate thermal solutions for heat dissipation from print heads electronics

• Experience in supporting a manufacturing environment and the quality of the maintenance services provided to costumers

• Solid knowledge in DF’x such as design for Manufacturing, and Low cost

• Work with large datasets and distributed computing tools using JMP(SAS) program, Visual Basic, Reliasoft (Weibull++, ALTA, BlockSim) and Excell

• Working Knowledge of RoSH and UL standards

• Solid knowledge in Failure Modes and Effect Analysis (FMEA) tool to define reliability tests

• Heat Transfer, Fluid dynamics, Big Data analysis, CFD – area of interest and my hobby

• Master of Science (M.Sc.) of Mechanical Engineering

• Hold 15 US patents and published articles in printing journal

Education:

Master of Science (M.Sc.) in Mechanical Engineering

Engineering, for me, is both a profession and a passion — especially in the fields of heat transfer, fluid dynamics, and big data analysis.

Read Our Latest Blogs

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

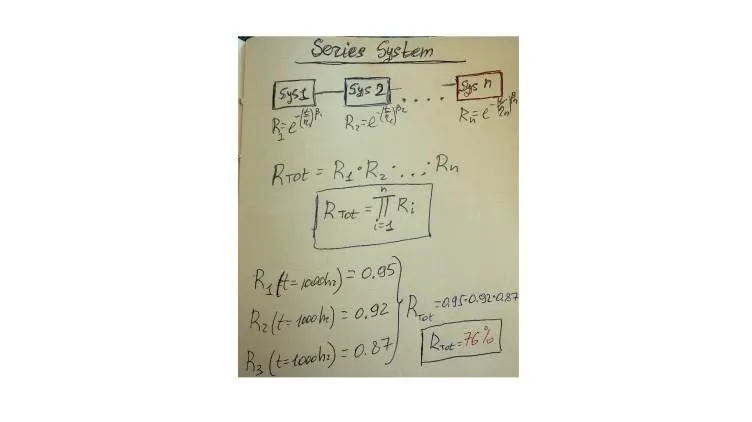

Series-Connected Subsystems

The moment an electromechanical product is laid out as a string of dependent subsystems, its overall reliability begins to behave very differently from the robustness of any single part. When the subsystems are connected in series—meaning the product fails if any one of them fails—the total reliability at a given mission time is the simple product of the individual reliabilities. Even if each block is impressively dependable on its own, multiplying several values less than 1.0 quickly drives the composite figure downward. A device assembled from five modules that are each 0.95 reliable across the warranty period only achieves 0.77 overall reliability; with ten such modules, the figure plunges to 0.60. The arithmetic makes clear that engineers must either raise the reliability of the weakest subsystems, insert redundancy, or shorten the specified lifetime if they hope to uphold a customer-facing reliability target.

Because the reliability numbers you plug into that product equation must reflect reality, the quality of the data source is pivotal. Field-return statistics—calendar-time records from actual customers—deliver the most authentic picture of real-world duty cycles, variable stresses, and environmental surprises. They capture interactions that laboratory tests may overlook, such as shipping-induced wear or misuse. However, field data arrive slowly and often noisily; separating infant mortality from random failures requires large populations and months—or years—of monitoring.

Accelerated life testing (ALT) offers a faster route. By elevating stressors such as temperature, vibration, or duty cycle, ALT coaxes failures to appear in days or weeks instead of seasons. Recording time-to-failure under these controlled but intensified conditions, then translating the results back to normal use via physics-of-failure or statistical acceleration models, yields early reliability estimates that guide design choices while prototypes are still malleable. Yet ALT is only as good as its acceleration model: misuse of Arrhenius, Coffin-Manson, or Miner’s rule can skew the extrapolation and breed overconfidence.

The art is therefore to blend both sources. Early in development, ALT provides a directional signal—identifying weak links, supporting design-for-reliability decisions, and feeding preliminary series-system calculations. Once the product launches, field data replace assumptions with facts, allowing recalculation of subsystem reliabilities and, by extension, the series product’s mission-success probability. A feedback loop emerges: if the updated series-reliability projection falls short of the market requirement, engineering has three levers—boost the life of a troublesome subsystem, add parallel redundancy, or renegotiate the specified lifetime.

Finally, remember that the series model is unforgiving but also illuminating. It quantifies the intuition that “a chain is only as strong as its weakest link” and translates it into actionable math. By combining trustworthy time-to-failure data—whether harvested patiently from the field or accelerated aggressively in the lab—designers can predict, compare, and, most importantly, improve the reliability trajectory of complex electromechanical devices before the customer ever flips the power switch.

© 2025- All Rights Reserved.