About Me

From product vision to measurable results

• 15 years of experience in a R&D, manufacturing environment, experience with multidisciplinary team in the Large Format Printing, Automotive, Hydrogen Fuel Cell and Medical industries.

• RTF (run to failure approach), Weibull++ analysis of data, test definition

• Experienced in test definition through tools such as Design Of Experiment (DOE) and Root Cause Diagram (RCD)

• Experience in product validation, product development processes

• Experienced in CFD (ANSYS CFX) and thermal mockups to validate thermal solutions for heat dissipation from print heads electronics

• Experience in supporting a manufacturing environment and the quality of the maintenance services provided to costumers

• Solid knowledge in DF’x such as design for Manufacturing, and Low cost

• Work with large datasets and distributed computing tools using JMP(SAS) program, Visual Basic, Reliasoft (Weibull++, ALTA, BlockSim) and Excell

• Working Knowledge of RoSH and UL standards

• Solid knowledge in Failure Modes and Effect Analysis (FMEA) tool to define reliability tests

• Heat Transfer, Fluid dynamics, Big Data analysis, CFD – area of interest and my hobby

• Master of Science (M.Sc.) of Mechanical Engineering

• Hold 15 US patents and published articles in printing journal

Education:

Master of Science (M.Sc.) in Mechanical Engineering

Engineering, for me, is both a profession and a passion — especially in the fields of heat transfer, fluid dynamics, and big data analysis.

Read Our Latest Blogs

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

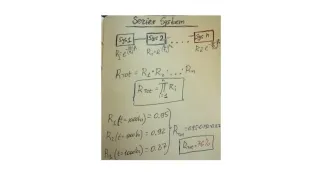

Series-Connected Subsystems

Complex electromechanical products rarely rely on a single mechanism; they knit together motors, sensors, power electronics, and software into an interdependent whole. When these blocks are wired in s... ...more

DOE

September 05, 2025•2 min read

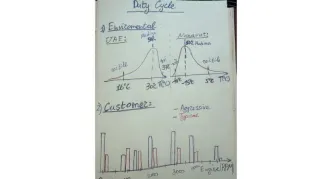

Duty Cycle Engineering

A clearly defined duty cycle—the time-weighted map of every load, rest period and environmental exposure a product sees—anchors both design and testing. When engineers know how long a motor will dwell... ...more

DOE

September 05, 2025•3 min read

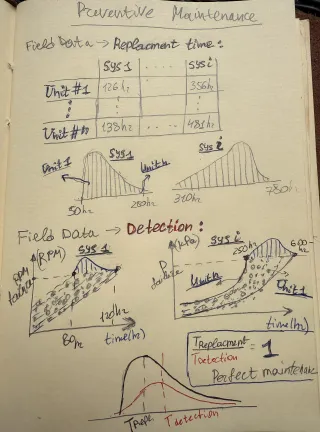

Preventive maintenance: Replacement vs. Detection

Two mindsets dominate preventive maintenance. Time-based replacement swaps parts after a fixed number of hours, cycles, or calendar days; its simplicity and regulatory compliance keep it the workhorse... ...more

Friction ,DOE &Data

September 05, 2025•2 min read

© 2025- All Rights Reserved.