About Me

From product vision to measurable results

• 15 years of experience in a R&D, manufacturing environment, experience with multidisciplinary team in the Large Format Printing, Automotive, Hydrogen Fuel Cell and Medical industries.

• RTF (run to failure approach), Weibull++ analysis of data, test definition

• Experienced in test definition through tools such as Design Of Experiment (DOE) and Root Cause Diagram (RCD)

• Experience in product validation, product development processes

• Experienced in CFD (ANSYS CFX) and thermal mockups to validate thermal solutions for heat dissipation from print heads electronics

• Experience in supporting a manufacturing environment and the quality of the maintenance services provided to costumers

• Solid knowledge in DF’x such as design for Manufacturing, and Low cost

• Work with large datasets and distributed computing tools using JMP(SAS) program, Visual Basic, Reliasoft (Weibull++, ALTA, BlockSim) and Excell

• Working Knowledge of RoSH and UL standards

• Solid knowledge in Failure Modes and Effect Analysis (FMEA) tool to define reliability tests

• Heat Transfer, Fluid dynamics, Big Data analysis, CFD – area of interest and my hobby

• Master of Science (M.Sc.) of Mechanical Engineering

• Hold 15 US patents and published articles in printing journal

Education:

Master of Science (M.Sc.) in Mechanical Engineering

Engineering, for me, is both a profession and a passion — especially in the fields of heat transfer, fluid dynamics, and big data analysis.

Read Our Latest Blogs

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

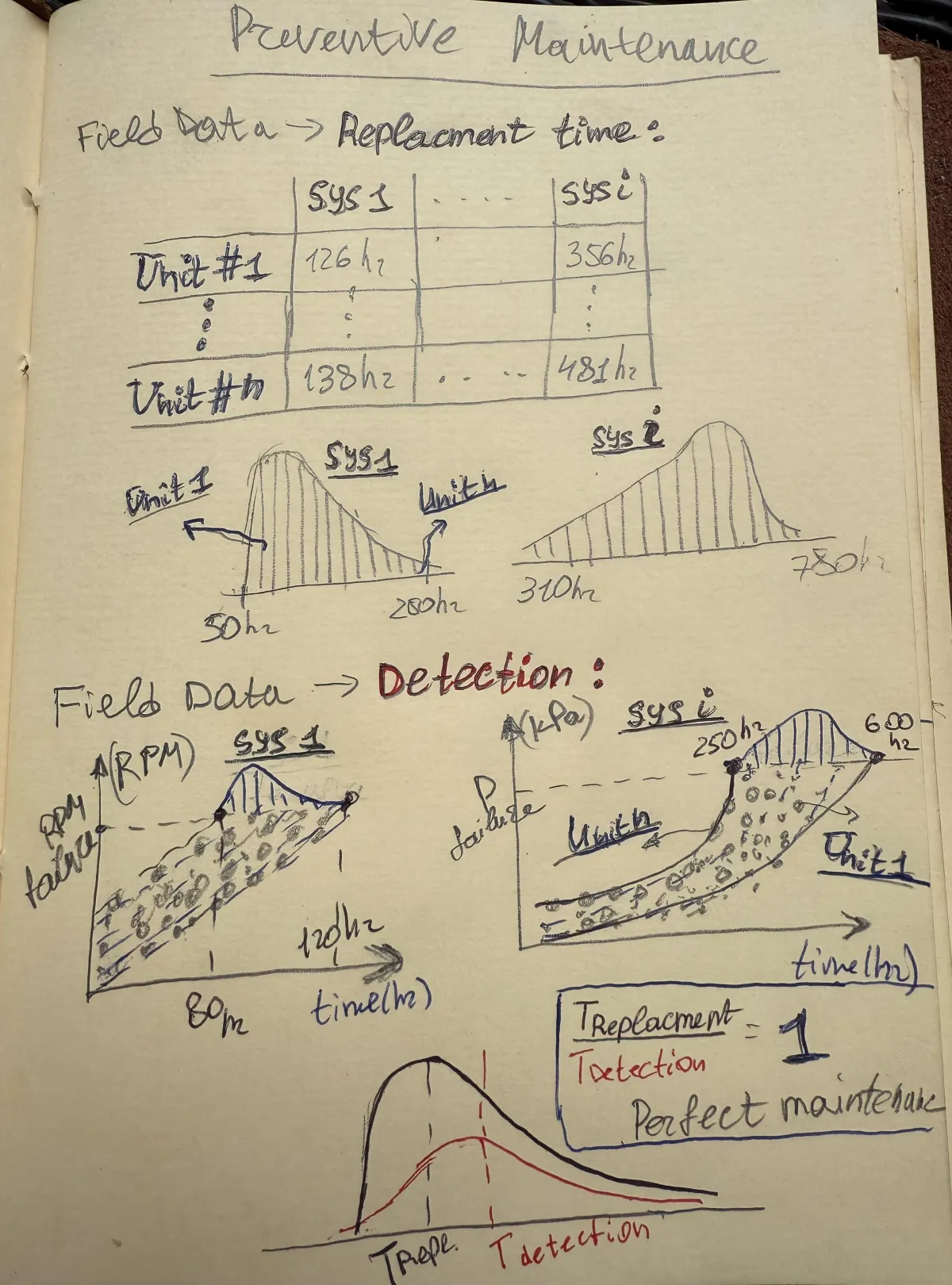

Preventive maintenance: Replacement vs. Detection

Preventive maintenance boils down to a single question: When should we act before a failure acts on us? Two dominant schools of thought answer differently. A time-based replacement program schedules service after a fixed number of hours, cycles, or calendar days, betting that history is a good proxy for future risk. A condition-based detection program monitors a health indicator—vibration, temperature, pressure drop—and intervenes the moment that signal crosses an alarm limit. Understanding how they contrast is essential for designing a maintenance plan that balances uptime, cost, and risk.

Time-based replacement is the simpler path. You gather run-to-failure data, pick an interval comfortably before the average wear-out age, and standardize it across the fleet. The upside is predictability: parts, labor, and downtime can be budgeted a year in advance, and no sensors or analytics infrastructure are required. The downside is waste and blindness. Healthy assets are retired with useful life still inside, while abnormal early failures remain invisible until they bite because the calendar, not the machine, sets the schedule.

Condition-based detection turns that logic around. Instead of predicting failure statistically, it measures degradation directly. A bearing’s crest factor, a pump’s discharge pressure ripple, or a motor’s winding temperature becomes a real-time window into wear. Interventions happen only when a specific unit signals distress, extracting maximum life from benign assets and catching outliers before they cascade into secondary damage. The trade-offs are upfront investment in sensors and data pipelines, plus the continuous tuning of alarm thresholds as operating conditions evolve.

Many reliability teams blend the two into a hybrid policy. A conservative replacement ceiling acts as a safety net against sensor blind spots, while condition-based triggers drive day-to-day decisions. This layered approach delivers both predictability and responsiveness: if the data stream goes dark, the replacement interval still protects uptime; if the data stream is healthy, detections fine-tune interventions to the actual wear curve.

Implementation success hinges on organizational readiness, not just technology. Planners must align spare-parts logistics with variable detection dates, technicians need training to trust sensor alarms over habit, and finance teams should recognize that higher first-year costs for instrumentation often pay back through reduced catastrophic failures. Equally important, data science and domain expertise must collaborate; a great algorithm without field-savvy validation can trigger as many false positives as a miscalibrated pressure gauge.

Ultimately, the replacement vs detection debate is less an either-or choice than a slider you adjust for business criticality, budget, and risk appetite. Low-cost consumables with no measurable precursor still make sense on a fixed schedule, while high-value assets that telegraph their health deserve the nuance of condition monitoring. The reliability engineer’s craft lies in dialing that slider to where cost, complexity, and confidence converge—pre-empting downtime without overspending on insurance policies disguised as maintenance.

© 2025- All Rights Reserved.