Get in Touch

Whether you want to collaborate, discuss product strategy, or explore speaking opportunities — I’d love to connect.

Read Our Latest Blogs

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Duty Cycle Engineering

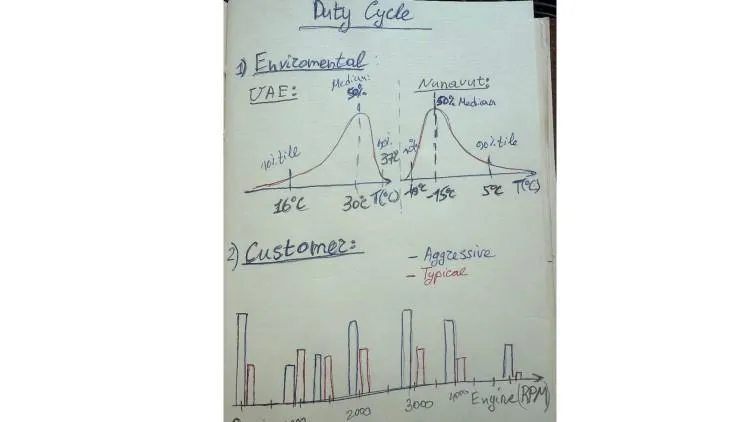

In reliability engineering, the duty cycle is a concise description of how long and how hard a component is expected to work, and under which environmental and operational conditions it must survive for the life of the product. A well-constructed duty cycle captures the time history of all relevant stresses—thermal, mechanical, electrical, chemical—and translates that history into quantifiable test conditions that assure field performance.

When the same component must operate in climatically opposite regions, the temperature portion of the duty cycle widens dramatically. A consumer device sold in the Emirates may sit in a parked vehicle at 80 °C cabin temperature and 95% relative humidity, then be carried into an air-conditioned office at 22 °C. The identical device shipped to North Canada could see −40 °C during outdoor use, then be warmed in a heated cabin within minutes. These rapid, high-magnitude excursions cause coefficient-of-thermal-expansion (CTE) mismatches, moisture pumping, and condensation inside seals. Designers therefore build a composite thermal-humidity duty cycle that superimposes the hottest humid dwell, the coldest dry soak, and the transition rate between them. Thermal cycling chambers with controlled humidity, combined with powered operation to add self-heating, are typically used to validate that solder joints, polymers, and seals endure both ends of the spectrum.

Customer utilization adds a second dimension. A “high-care” user may power the product only during work shifts, store it in its protective case, and follow maintenance schedules. A “negligent” user might leave it powered continuously, expose it to coffee spills, drop it on concrete, and ignore warning lights. Although both users share the same environmental envelope, their operational duty cycles diverge in on-time, load profile, and incidental mechanical shock. Reliability engineers model this spread either by allocating statistical weights—such as 60% typical users, 30% aggressive, 10% abusive—or by building separate test flows that target each persona. Field data loggers, IoT telemetry, and returned-unit tear-downs supply the empirical evidence needed to justify where the product boundary truly lies between intended use and misuse.

Choosing the right parameters to build typical, aggressive, and abusive duty cycles is often debated because over-testing wastes cost and under-testing invites field failures. Temperature and humidity remain primary because most failure mechanisms accelerate exponentially with heat and react strongly to moisture. Mechanical vibration and shock are next in importance for mobile or automotive products; they introduce high-cycle fatigue that electrical tests alone cannot reveal. Electrical stress—including voltage overshoot, inrush current, and reverse polarity—matters for electronics but can often be decoupled from thermal stress if dissipation is low. Chemical exposure, ultraviolet radiation, and particulate contamination round out the list for outdoor or industrial equipment. The weighting of each parameter depends on three pillars: 1) the physics of failure of the dominant mechanisms, 2) the statistical prevalence of each stress in the field, and 3) the economic or safety consequence of failure.

Test methods are mapped to these tiers of duty cycle severity. For “typical” duty cycles, extended duration tests at nominal conditions—such as year-long powered aging or 1000-hour thermal storage—verify wear-out life and corrosion resistance. “Aggressive” duty cycles rely on accelerated profiles: temperature-humidity bias, rapid thermal cycling, or vibration with 6-degree-of-freedom tables, all at levels still within the spec sheet. Acceleration factors are calculated with Arrhenius, Eyring, or Coffin-Manson models to maintain failure equivalence while shortening calendar time. “Abusive” duty cycles intentionally exceed specification limits to uncover margin: HALT/HASS pushes temperature, vibration, and voltage until the weakest link breaks; drop testing to concrete from two meters probes enclosure integrity; salt-fog immersion reveals sealing flaws. While abusive testing is not intended to predict life quantitatively, it guides design margin and screens manufacturing escapes.

Balancing these layers requires iteration. Begin with a physics-based durability model, overlay statistically weighted field data, and negotiate acceptable risk with stakeholders. The final duty cycle matrix then drives sample size, instrumentation points, and pass-fail criteria for each reliability build, ensuring that a single component can thrive from the scorching humidity of the Gulf to the sub-arctic chill of northern Canada, and from the pampered hands of meticulous users to the rough treatment of the indifferent.

© 2025- All Rights Reserved.