About Me

From product vision to measurable results

• 15 years of experience in a R&D, manufacturing environment, experience with multidisciplinary team in the Large Format Printing, Automotive, Hydrogen Fuel Cell and Medical industries.

• RTF (run to failure approach), Weibull++ analysis of data, test definition

• Experienced in test definition through tools such as Design Of Experiment (DOE) and Root Cause Diagram (RCD)

• Experience in product validation, product development processes

• Experienced in CFD (ANSYS CFX) and thermal mockups to validate thermal solutions for heat dissipation from print heads electronics

• Experience in supporting a manufacturing environment and the quality of the maintenance services provided to costumers

• Solid knowledge in DF’x such as design for Manufacturing, and Low cost

• Work with large datasets and distributed computing tools using JMP(SAS) program, Visual Basic, Reliasoft (Weibull++, ALTA, BlockSim) and Excell

• Working Knowledge of RoSH and UL standards

• Solid knowledge in Failure Modes and Effect Analysis (FMEA) tool to define reliability tests

• Heat Transfer, Fluid dynamics, Big Data analysis, CFD – area of interest and my hobby

• Master of Science (M.Sc.) of Mechanical Engineering

• Hold 15 US patents and published articles in printing journal

Education:

Master of Science (M.Sc.) in Mechanical Engineering

Engineering, for me, is both a profession and a passion — especially in the fields of heat transfer, fluid dynamics, and big data analysis.

Read Our Latest Blogs

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

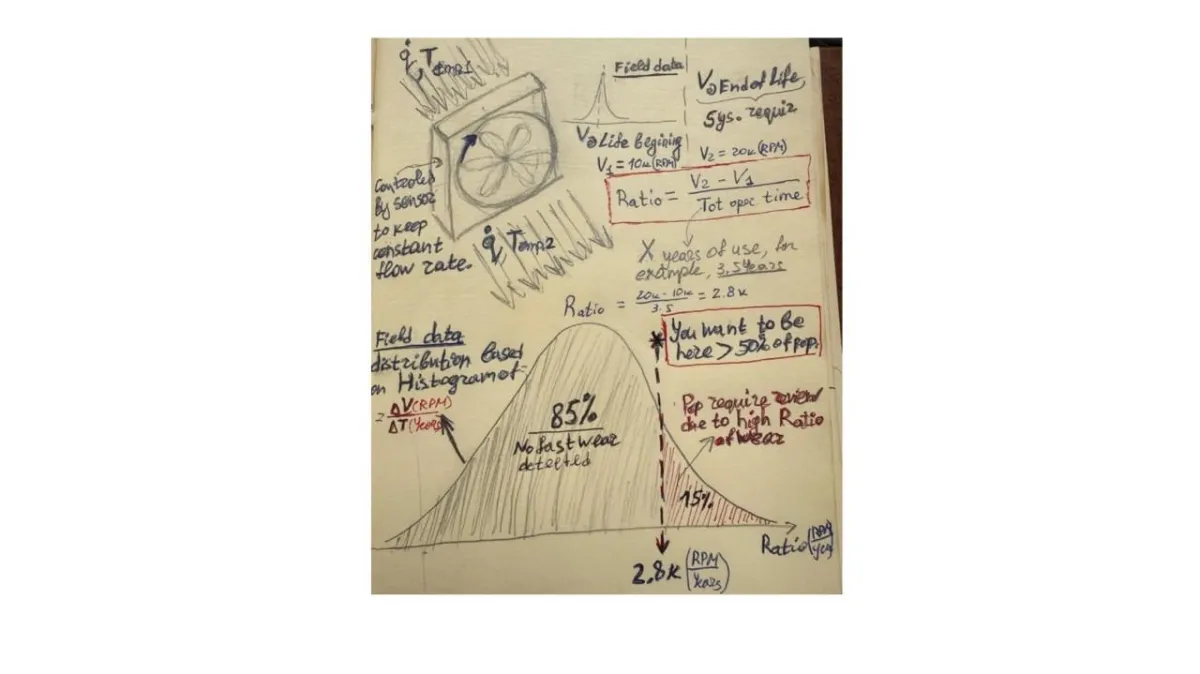

Data-Driven Detection of Accelerated Wear in Critical System Components.

Detecting fast wear populations is a critical aspect of reliability engineering for all essential components in mission-critical systems. By identifying outliers in wear rates, maintenance strategies can be optimized, failures can be anticipated, and overall system integrity is protected. In this article, the methodology is illustrated using the example of server room cooling fans—a component vital for maintaining safe temperatures and ensuring the operational stability of sensitive electronics.

For cooling fans, wear is most effectively monitored through sensor data logging the rotational speed (RPM). Each unit starts with an initial value established at the production line, averaging around 10k RPM. Over its service life, wear and load increments gradually raise the RPM, and system requirements dictate a maximum, or end-of-life (EOL), value of 20k RPM—beyond which proper airflow cannot be guaranteed without breaching power constraints.

These fans are scheduled for replacement every 3.5 years, so the optimal annual wear rate is (20k-10k)/3.5 years, or roughly 2.86k RPM per year. With more than 100k fans operating in the field, field data is aggregated to form a distribution curve of these wear rates. Ideally, over 85% of the fan population should exhibit an annual wear rate of 2.8k RPM/year or less, signaling normal aging and healthy operation.

The remaining 15% of fans displaying higher-than-expected wear rates form the fast wear population, which demands further analysis. Several factors may contribute to this accelerated wear: variability in supplier quality, differences in duty cycles, environmental aggressiveness (such as higher temperatures or humidity), or region-specific stresses. By isolating these high-wear cases through focused data segmentation and analysis, the organization can target root causes—whether that means upgrading supplier requirements, refining duty cycles, or customizing maintenance intervals. Recognizing and managing fast wear populations ultimately enhances overall reliability, reduces unplanned downtime, and supports continuous improvement for all critical system components.

© 2025- All Rights Reserved.